In this blog, we’ll take a closer look at unified namespace software and why it’s becoming essential for modern manufacturing environments. You’ll learn how this software enables real-time data sharing across IT and OT systems, the key components of a unified namespace architecture, and which tools are best suited to support it. We’ll also highlight how dataPARC fits into this ecosystem by helping manufacturers create a single, structured source of truth that improves visibility, efficiency, and decision-making.

Break Data Silos and Gain Real-Time Visibility Across Your Enterprise with PARCview

Why Unified Data Matters in Industrial Operations

More and more, we are seeing industrial facilities generating enormous amounts of data. Machines, sensors, and systems are constantly collecting information, production rates, energy consumption, quality metrics, and more. But often, there is a problem: that data is scattered across disconnected platforms.

SCADA, historians, MES, or ERP all hold pieces of the puzzle yet rarely fit together in real time. Engineers pull reports from one system, operators rely on another, and IT manages a separate database entirely. The result? Decisions take a long time. Critical insights slip through the cracks. Productivity suffers.

A Unified Namespace (UNS) offers a path forward. It’s not just another software tool or one-size-fits-all solution. Instead, it’s a structured approach to organizing and sharing industrial data in real-time. The goal? Break down silos, improve visibility, and make data easily accessible across IT and OT.

But here’s the catch: not every company needs a rigid, full-scale UNS deployment. Instead of overhauling entire systems, businesses can take a practical approach, integrating key data sources, building real-time dashboards, and connecting IT and OT step by step.

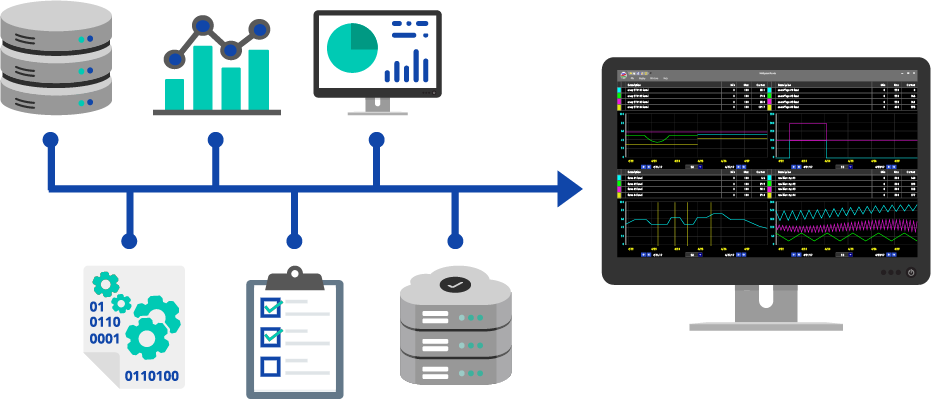

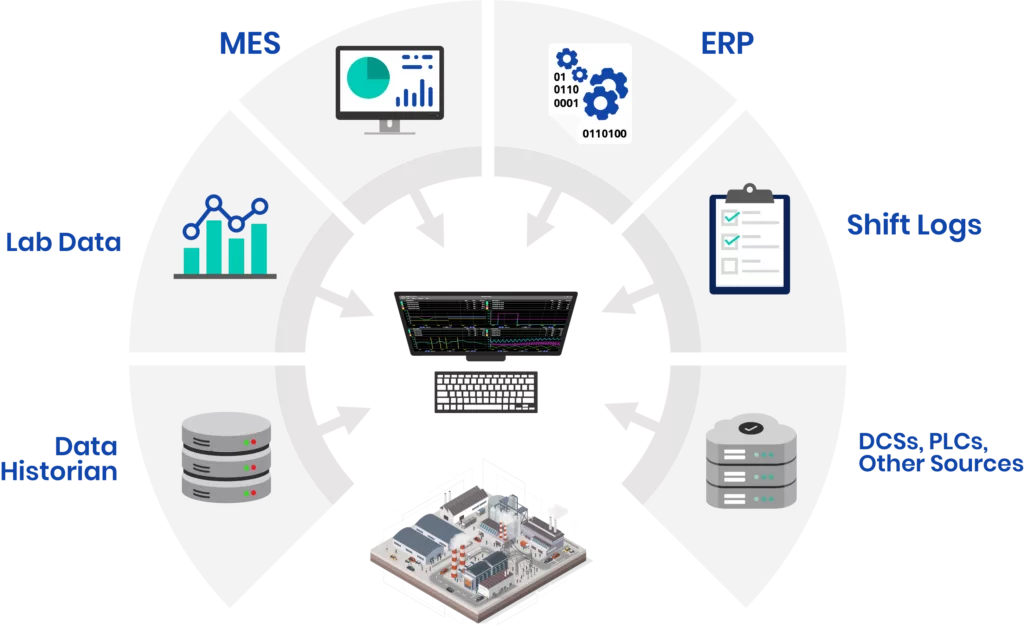

With Unified Namespace software, process data, lab data, ERP, and MES seamlessly integrate into a real-time monitoring system, allowing for unified visualization, trend analysis, and improved production troubleshooting to maximize uptime.

Core Software Components of UNS

Finding the right unified namespace software isn’t about buying a single all-in-one platform, it’s about strategically integrating the right tools to connect, process, store, and visualize industrial data. Whether your goal is full UNS adoption or simply reducing system fragmentation, these software components play a key role in making it happen.

Message Brokers & Middleware: The Data Traffic Controllers

To keep industrial data flowing smoothly, you need software to route, transform, and distribute information between different systems. Middleware solutions act as the glue between IT and OT, ensuring that SCADA, MES, ERP, and cloud platforms exchange data efficiently. Even if you’re not using a dedicated broker, middleware solutions can create structured data pipelines without requiring a full architecture shift.

Data Collection: Getting Data Where It Needs to Go

Raw industrial data is fast-moving and high-volume. Collecting and processing it at the edge, closer to production equipment, reduces latency and ensures real-time data availability. Edge gateways, industrial IoT devices, and embedded computing solutions are crucial in structuring data before it reaches the broader UNS framework.

Data Historians: The Memory of Your Operations

A UNS needs a strong foundation for data storage and retrieval. That’s where historians come in. They capture high-resolution time-series data from sensors, control systems, and production lines, making it available for deeper analysis. Connecting your historian to the UNS framework ensures that historical data can be combined with real-time insights for better decision-making.

Visualization & Analytics: Turning Data into Actionable Insights

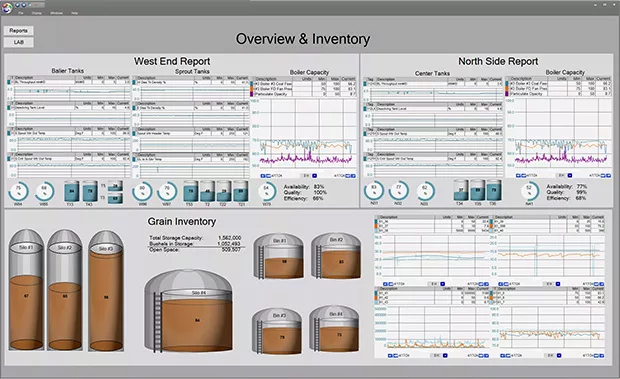

Data is only useful if the right people can access and understand it. Dashboards, trend analysis tools, and real-time monitoring software bring UNS data to life. Operators use them to monitor process trends. Engineers rely on them for root cause analysis. Supervisors track KPIs and production efficiency.

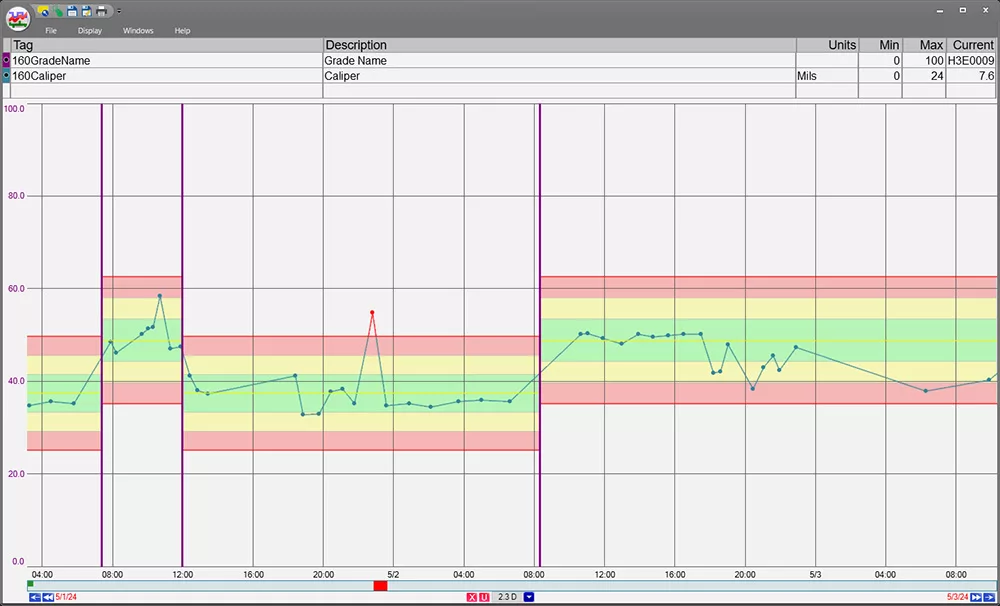

This sample dashboard illustrates how data can come in from multiple sources and appear on a single dashboard for operators to monitor and track data.

Cloud & Enterprise Integration: Scaling Beyond the Plant Floor

Truly effective UNS software doesn’t just unify plant-floor data, it connects it with enterprise systems. Cloud platforms, ERP systems, and business intelligence tools integrate with UNS frameworks to provide company-wide visibility. Whether it’s sending production data to corporate dashboards or feeding AI-driven predictive models, cloud and enterprise integration ensures that industrial data drives business-wide improvements.

Finding the right Unified Namespace Software isn’t about replacing everything; it’s about connecting everything. By choosing the right mix of these software components, companies can build a practical, scalable, and future-ready data infrastructure that supports real-time decision-making and continuous improvement.

Where dataPARC Fits in the UNS Software Stack

A Unified Namespace isn’t just about centralizing data, it’s about making it accessible, actionable, and useful across IT and OT. That’s exactly where dataPARC fits in. Instead of forcing a rigid architecture or requiring a full system overhaul, dataPARC provides a practical, flexible bridge between IT and OT, enabling real-time visibility and streamlined data integration.

Manufacturing data integration platforms with dataPARC help connect all the sources into a single source of truth, giving users seamless access to the information they need.

Seamless IT/OT Data Integration

One of the biggest challenges in industrial data management is the disconnect between operational technology (OT) systems, like SCADA, PLCs, and historians, and information technology (IT) systems, like ERP, cloud platforms, and business intelligence tools. dataPARC acts as a data aggregator, connecting these disparate sources into a single, real-time environment where teams can analyze and act on complete, contextualized data.

Real-Time Data Visualization & Analytics

A UNS isn’t just about collecting data, it’s about delivering insights where they matter. dataPARC’s trend analysis, dashboards, and alarm tools provide real-time visibility across production, quality, and enterprise-level KPIs. Operators can monitor live process data, engineers can correlate trends with historical performance, and managers can make data-driven decisions, all from one centralized platform.

Real-time production monitoring in action, a process limit is reached, triggering an alarm for immediate response and faster issue resolution.

Bridging Legacy & Modern Systems

Many companies hesitate to adopt a UNS approach because they fear it requires replacing existing systems. dataPARC eliminates that concern. It integrates with legacy and modern infrastructure alike, ensuring that historical data, lab results, ERP transactions, and IoT sensor readings all contribute to a single, structured data environment. Whether a company uses SQL databases, cloud applications, or on-prem solutions, dataPARC gets data flowing efficiently across the entire operation.

Making Unified Data Usable, Not Just Collectible

Even in environments that have already built out a UNS, dataPARC enhances usability by transforming raw data into meaningful, visual, and interactive reports. Its centerline, run browser, and statistical analysis tools allow manufacturers to spot trends, identify anomalies, and optimize production in real-time.

Bottom line: A Unified Namespace isn’t about adopting a single piece of software, it’s about integrating data effectively. dataPARC is the key visualization and analytics layer that makes industrial data actionable within a UNS strategy. Whether you’re just starting to unify data sources or looking for a powerful real-time analytics tool to complement your existing UNS, dataPARC helps bridge the gap between IT and OT, without adding unnecessary complexity.

Thinking about an Industrial Data Platform? Let our Digital Transformation Roadmap guide your way.

Steps to Implement a Unified Namespace with the Right Software

As we’ve discussed, building a Unified Namespace shouldn’t be about ripping out existing systems and starting over. It’s about strategic integration, connecting the right tools in a structured way to improve real-time visibility and decision-making. Here’s how to do it effectively:

1. Assess Your Current Infrastructure

Before implementing a UNS, you must map out your existing data landscape. Identify where data silos exist, what systems are already in place, and how information flows between IT and OT. This assessment will help determine the best integration points and whether existing tools can be leveraged or if new solutions are needed.

2. Select the Right Combination of Tools

A UNS isn’t a single software solution; it’s a framework that combines message brokers, historians, visualization platforms, and enterprise integration tools. Depending on your needs, you may require:

- Data integration tools to bridge IT/OT gaps (e.g., dataPARC, Kepware).

- Historians or databases for structured data storage (e.g., dataPARC Historian, AWS IoT SiteWise).

- Visualization and analytics for real-time decision-making (e.g., dataPARC’s PARCview).

Choosing tools that work together seamlessly is more important than following a rigid, one-size-fits-all approach.

3. Deploy in Phases

Rolling out a UNS across an entire organization all at once can be overwhelming. Instead, start small.

- Begin with a critical process area (e.g., a production line or energy monitoring system).

- Ensure data is accessible and actionable in real-time.

- Expand in stages, connecting additional systems and departments once the framework is stable and effective.

This phased approach minimizes disruptions and allows teams to adapt gradually.

4. Train Teams on Best Practices

A UNS is only as effective as the people using it. Operators, engineers, and IT teams need to understand how data is structured, where to access it, and how to use it for decision-making. Provide hands-on training, documentation, and best practice guidelines to ensure adoption across all levels of the organization.

By following these steps, companies can move toward a Unified Namespace in a way that is scalable, structured, and effective—without unnecessary complexity or disruption. The goal isn’t just to centralize data, but to make it accessible, actionable, and valuable for every user.

Conclusion & Next Steps

Industrial data is only as powerful as your ability to access and use it. Getting Unified Namespace Software together will help provide the structure needed to break down silos, improve real-time visibility, and drive better decision-making.

The key takeaway? There’s no one-size-fits-all solution. Instead of getting caught up in rigid definitions, focus on practical integration, choosing tools that bridge IT and OT, enable real-time visualization, and create a seamless data flow. Whether it’s dataPARC for intuitive dashboards, a historian for structured storage, or middleware for connectivity, the goal is to create a UNS that works for your specific needs.

So, what’s next? Start small. Evaluate your current data strategy, identify integration gaps, and test UNS-compatible tools in a proof-of-concept. A phased approach ensures a smooth transition, allowing you to unlock the benefits of a Unified Namespace without unnecessary disruption.

The future of industrial data is connected. The question is, how soon will you get there?