Discover an effective alternative to Yokogawa Exaquantum for streamlined data management. Find the best solutions to enhance your data strategy today!

Eliminate Lag with a High-Performance Data Platform Built for Scale

Choosing the Right Yokogawa Exaquantum Alternative

Industrial data management is a critical factor in operational efficiency. Its capabilities are well known for manufacturers relying on Yokogawa’s Exaquantum, a plant information management system (PIMS). It offers a cost-effective solution, often bundled as an extension of Yokogawa’s DCS, making it a widely used choice—especially in regions like Japan, where Yokogawa systems are prevalent.

However, just because a system is the regional standard doesn’t mean it’s the only or the best fit for every operation. While Exaquantum provides essential process data collection, visualization, and reporting, it comes with limitations that can impact the users and business:

- Limited data connectivity – Exaquantum primarily relies on OPC DA/OPC UA for data collection, with external system support restricted to APIs, OLE DB, OPC DA, and OPC UA.

- Security concerns – It lacks a dedicated data collection service, requiring direct server interfaces—posing a potential security risk, particularly with OPC DA.

- Performance bottlenecks – Handling large volumes of data slows down the system, reducing efficiency and scalability.

- User limitations – The system is heavy and sluggish when accommodating multiple users, making collaboration less effective.

- Tooling constraints – While functional, Exaquantum’s tools are not highly intuitive, limiting flexibility in analysis and visualization.

This is where dataPARC stands out. As a trusted solution across the globe and industries, dataPARC combines intuitive dashboards with advanced data integration. It provides real-time insights that drive smarter decisions. With a flexible, scalable approach, dataPARC adapts to your site’s specific needs—making it an ideal choice for those seeking an agile, high-performance alternative.

Understanding Exaquantum: A Data and Analytics Platform

Exaquantum has built a reputation as a process information management system. It enables industries to collect, visualize, and report data efficiently. In certain regions, particularly where Yokogawa DCS systems dominate, Exaquantum has been the go-to choice for managing complex data sets and integrating multiple sources using relational database management techniques.

While its affordability as an extension of Yokogawa’s DCS makes it attractive, its constraints reveal the need for more adaptable and scalable solutions. Performance issues with high data density, limited connectivity options, and security vulnerabilities highlight why many organizations are exploring more modern alternatives.

By evaluating these factors, manufacturers can ensure they’re using a data platform that meets today’s demands, not just one that fits within legacy system constraints.

Working on digital transformation at your plant? Let our Digital Transformation Roadmap guide your way.

Criteria for Choosing an Exaquantum Alternative

Choosing an alternative to Exaquantum isn’t a decision to make lightly. It’s about finding a tool that aligns with your business needs. So, what should you look for? Let’s break it down.

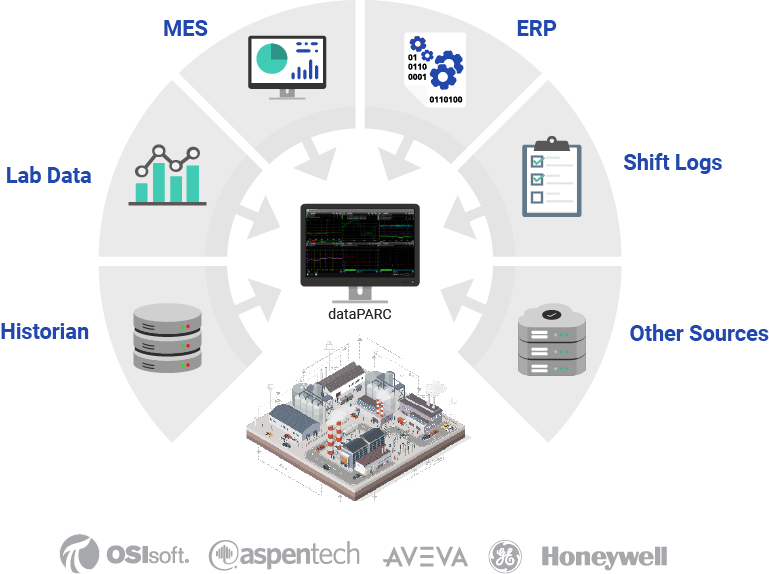

Data Integration

First and foremost: data integration capabilities. Any solution worth considering must connect with the various data sources your operation relies on. Real-time inputs, historical data, external data streams—your platform should handle them all without hiccups. The smoother the integration, the faster you can make informed decisions that drive results.

Additionally, critical data accessibility is essential to enhancing data governance and operational efficiency, ensuring users have access to essential data for making informed decisions. A ‘virtual source integrates data’ feature is crucial to enhancing asset performance and streamlining workflows by providing a unified view of disparate data without the need for data replication or migration.

Having a single source of truth through data integration helps keep everyone on the same page.

Scalability

Scalability is non-negotiable. Your data solution should grow as your business grows. A system that can’t scale efficiently will eventually become a bottleneck, costing you more in upgrades and time-consuming adjustments. It’s not just about today’s needs; it’s about where your company will be tomorrow.

Flexibility and Customization

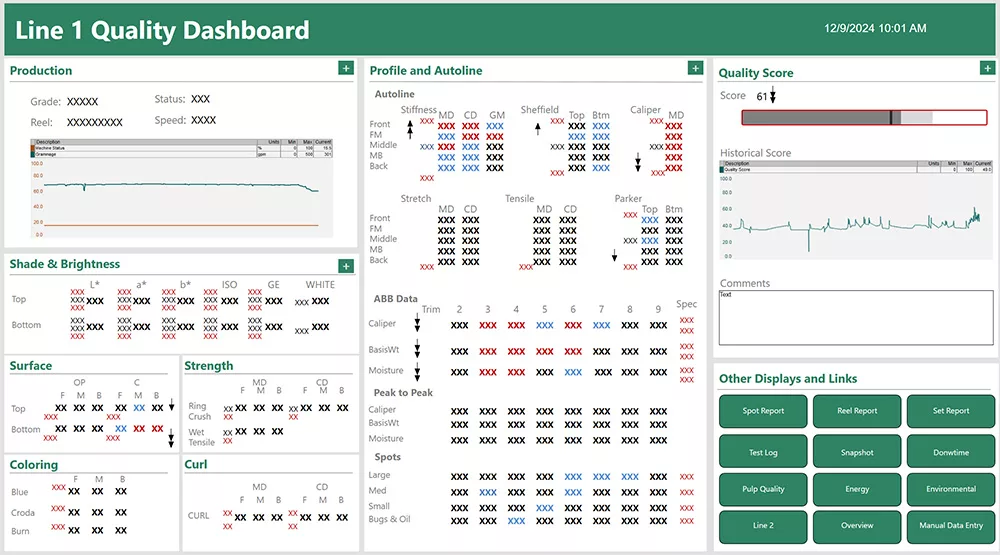

Next, customization and user experience. Don’t settle for rigid frameworks that make your team work harder than necessary. The right tool should be flexible, allowing you to tailor real-time manufacturing dashboards and reports to match your workflow. Plus, it should be user-friendly! Complex tools with steep learning curves waste time. Look for an intuitive interface that empowers your team to jump in and start optimizing from day one.

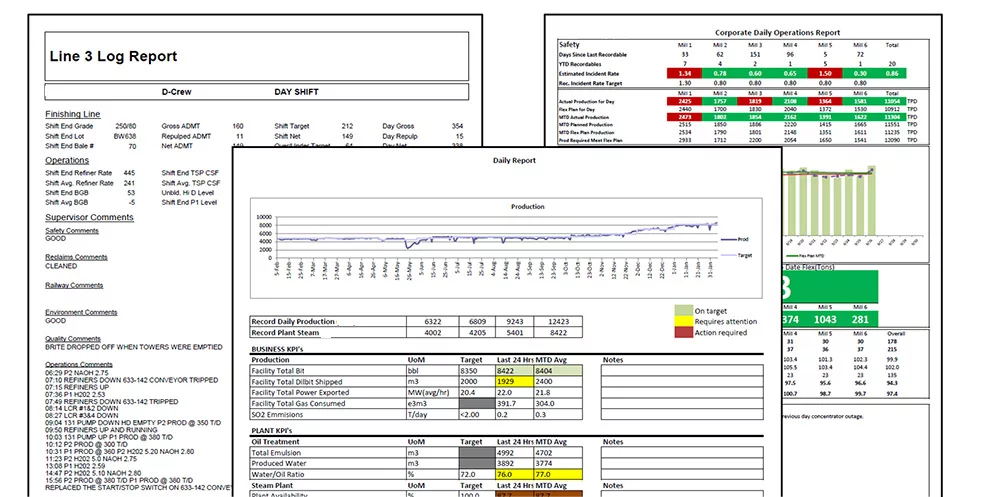

Dashboards are a great way to visualize and monitor process and KPI data on one screen.

Total Cost of Ownership

And, of course, cost-efficiency. Budgets matter, and with Exaquantum starting at such a low cost, any price tag could seem high. High upfront costs, hidden fees, or expensive licensing models can outweigh an otherwise promising option. Find a solution that balances functionality and affordability.

Data Analytics

Finally, don’t underestimate the power of real-time and historical data analysis. Your alternative should provide robust support for both, ensuring that you can monitor current operations and pull valuable insights from past trends. The combination of real-time tracking and historical analysis is the key to predictive insights and proactive decision-making. Equally important is the ability to control data quality and production data. All of these lead to more confident decision-making and effective management of data across various operational processes and teams.

Keep these criteria front and center as you weigh your options. The right choice can transform your data management from a static necessity to a dynamic advantage.

Exploring Alternatives: Highlighting dataPARC

When it comes to choosing an Exaquantum alternative, dataPARC stands out as a key competitor. Leveraging modern data analysis, dataPARC enhances operational capabilities through real-time data integration and visualization.

Data Integration

dataPARC excels at bringing data sources together. From real-time process data and historical trends to external inputs into a unified namespace. Its robust integration framework eliminates the need for extensive data replication or migration, saving time and reducing complexity.

By providing real-time accessibility and enhancing data governance, dataPARC ensures accurate, actionable insights that empower better decision-making and improve operational efficiency.

In a world where connectivity is key, dataPARC’s ability to adapt to unique systems and environments makes it a standout choice for manufacturers seeking a flexible, powerful data management solution.

Check out dataPARC’s real-time process data analytics tools & see how better data can lead to better decisions.

Scalability

dataPARC’s scalable architecture ensures growth as your operations expand. Whether adding new data sources, users, or sites, dataPARC handles increasing demands without compromising performance. Unlimited users mean no waiting on license upgrades to see your data. Robust infrastructure supports real-time insights and historical analysis, even with large datasets. Future-ready and adaptable, dataPARC ensures your system evolves with your business needs, delivering reliability at every stage.

Flexibility and Customization

One of dataPARC’s greatest strengths lies in its ability to adapt to the unique requirements of any operation. Unlike rigid systems, dataPARC offers unmatched flexibility, allowing users to customize dashboards, calculations, reports, and workflows to align seamlessly with their specific processes.

Graphics and Visualizations

dataPARC’s intuitive interface empowers users to create detailed, user-friendly graphics that provide real-time insights into operations. Customizable visualizations make it easy to monitor critical KPIs, identify trends, and communicate complex data to teams at all levels. Whether tracking production metrics or analyzing environmental compliance, dataPARC’s graphics capabilities ensure your data is accessible and actionable.

Alarms and Alerts

Customization doesn’t stop at visuals—dataPARC’s advanced alarm management system informs you of critical changes in real-time. Users can configure alarms to flag deviations, equipment failures, or threshold breaches, ensuring issues are addressed before escalating. These alerts can be tailored to specific operational priorities, giving your team the tools to maintain efficiency and minimize downtime.

Always be informed with real-time production monitoring and have alarms emailed or texted to you. Attach images of graphics, trends, or even links.

By combining these customization options with increased functionality, dataPARC empowers manufacturers to design a solution that perfectly fits their needs. This enhances productivity and drives smarter decisions across the organization.

Total Cost of Ownership

dataPARC offers a cost-effective solution that balances functionality with affordability. With flexible licensing options and minimal reliance on third-party tools, dataPARC reduces upfront costs and ongoing expenses. Its ease of implementation and intuitive interface minimize training time and operational disruptions, further lowering total ownership costs. dataPARC ensures you get maximum value from your investment by providing robust capabilities without hidden fees.

Data Analytics

dataPARC’s data analytics tools empower manufacturers to harness the full potential of their data. By combining real-time monitoring with historical access. dataPARC enables users to make informed decisions that drive operational efficiency and long-term success.

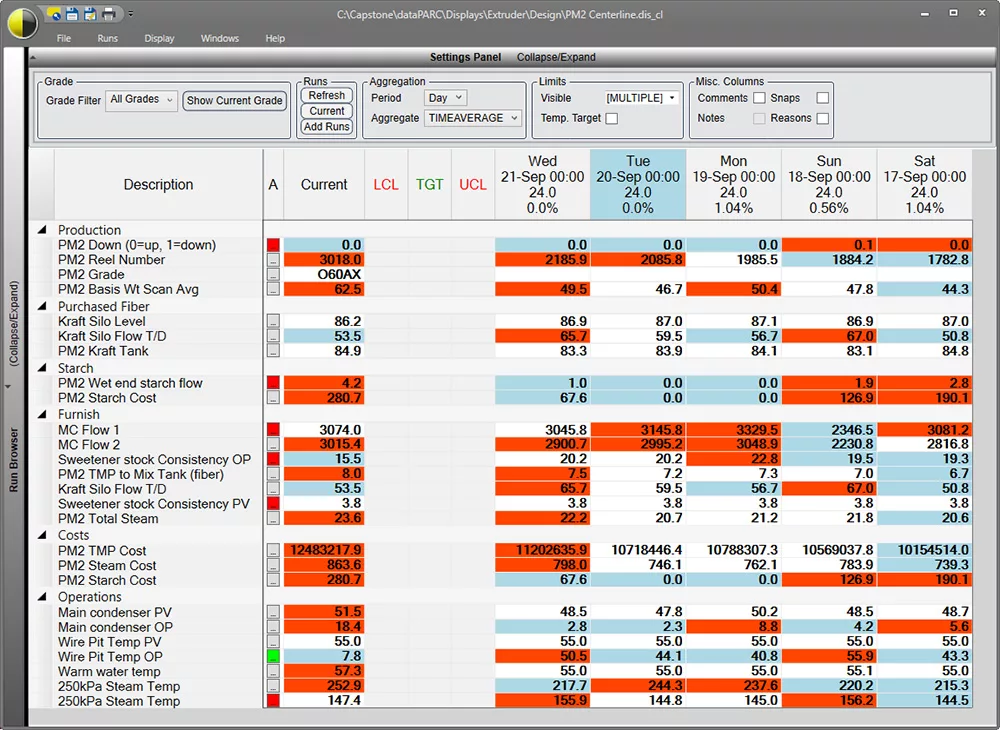

This Centerline display is a unique PARCview display that shows non-consecutive runs as if they were convective, in this case highlighting high and low values.

Real-Time Monitoring for Immediate Action

With dataPARC, you can track operations as they happen, identifying issues and opportunities in real-time. This capability is critical for optimizing production processes, reducing downtime, and maintaining product quality. Alerts and notifications ensure that teams are informed of critical changes immediately, enabling quick responses to potential problems.

Historical Analysis for Informed Planning

In addition to real-time insights, dataPARC offers powerful historical analysis tools that allow users to uncover trends, pinpoint recurring issues, and identify opportunities for improvement. This combination of past and present data helps organizations make proactive, data-driven decisions that enhance efficiency and sustainability.

Advanced Visualizations and Reporting

dataPARC’s customizable dashboards and graphics make it easy to analyze complex datasets and share insights across teams. Whether monitoring KPIs, comparing historical trends, or conducting root cause analysis, dataPARC’s visualizations ensure that data is accessible and actionable for all stakeholders.

Automated reporting to emails can be configured via workflows to create a customized experience for dataPARC customers.

By turning raw data into actionable insights, dataPARC transforms data analytics from a back-end function into a strategic advantage, helping manufacturers stay competitive in a fast-paced industrial landscape.

Overview of the dataPARC Historian

At the core of dataPARC lies a powerful historian designed to efficiently store and manage massive volumes of process data. This robust system enables real-time data capture and retrieval, ensuring that critical operational insights are always within reach. Unlike traditional systems, the dataPARC historian offers unparalleled performance, handling high-frequency data streams and large datasets effortlessly.

The historian connects to diverse data sources with seamless integration capabilities, providing a unified view of operations. Its intuitive interface and customizable access points empower users to explore trends, perform in-depth analyses, and generate meaningful reports easily. By combining speed, scalability, and reliability, the dataPARC historian is the foundation for informed decision-making and continuous operational improvement.

Next Steps: Choosing dataPARC for Your Data Management Needs

Having the right data management solution isn’t just helpful; it’s essential. While Exaquantum has been a convenient add-on to Yokogawa’s DCS, exploring alternatives can lead to better scalability, customization, and overall efficiency. The need for a robust, adaptable platform that fits seamlessly into your unique processes has never been clearer.

Enter dataPARC. It’s more than just a Yokogawa Exaquantum Alternative; it’s a solution built for the future. Not only that, but it is also a solution built by engineers for engineers. It’s proven to be a top choice globally. With strengths in real-time visualization, flexible reporting, and an interface that empowers users to move quickly. dataPARC offers the comprehensive capabilities your team needs to stay ahead of the curve. dataPARC’s ability to interpret complex data also sets it apart from other solutions.

Ready to see the difference firsthand? Assessing dataPARC could be the step that transforms how you manage and leverage data in your operations. Don’t just take our word for it—explore a demo, dive into the details, and see how it compares to your current system. The right choice isn’t just about staying competitive; it’s about thriving in an ever-changing landscape.